SAP for Sludge and Liquid Waste Solidification

Sediments and sludge are dense, semi-liquid waste materials characterized by a high solid content. Common examples include dredged harbor sludge, polluted lagoon deposits, drilling mud residues, mining tailings, landfill leachate, treated biosolids from wastewater, and coal ash pond slurry. These waste streams often require specialized handling and disposal due to their composition and potential environmental impact. Our super absorbent polymer is the high-efficient, cost-effective & eco-friendly choice for sludge, slurry and liquid waste treatment. You only need a small amount of it (usually 1% of the waste) to treat bulk liquid waste. The gel formed after absorption can firmly lock the water and prevent the liquid waste from leaking even under certain pressure, the volume expansion rate is less than 1%, which can reduce transportation and processing costs.

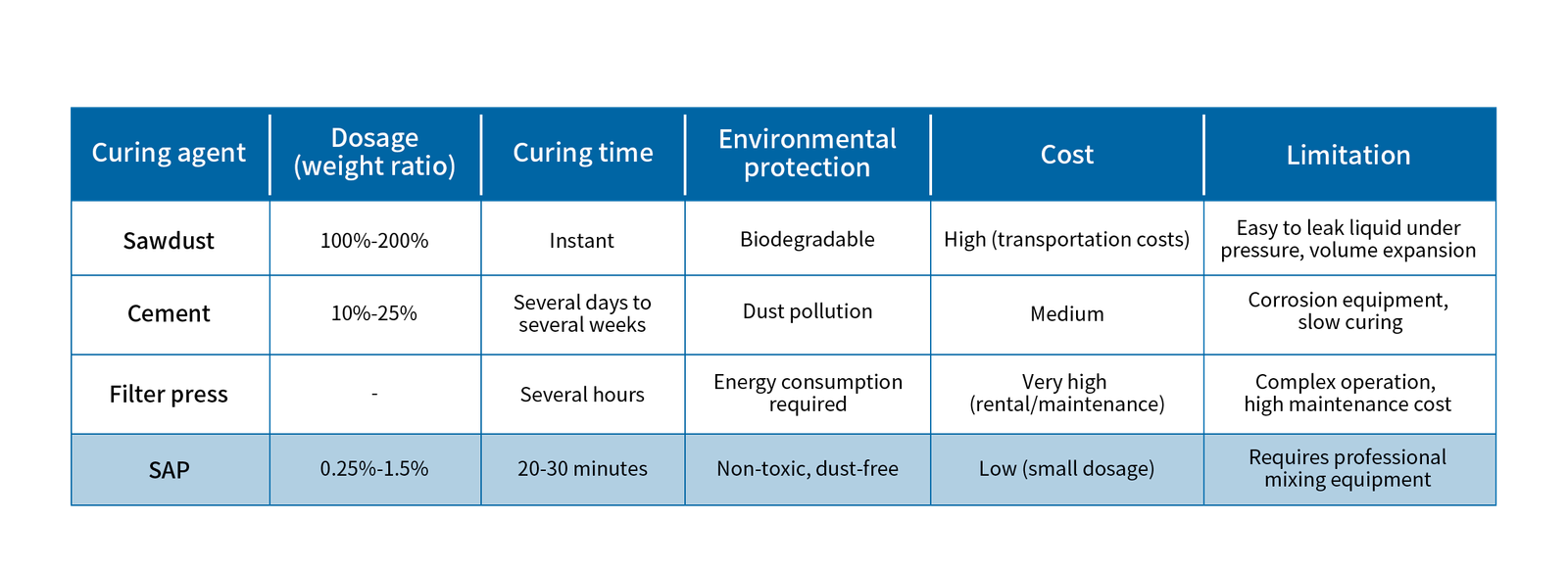

Comparison of Main Liquid Waste Solidification

Our Solution for Sludge and Liquid Waste Solidification

Our super absorbent polymer is extensively utilized to capture and immobilize free liquids, ensuring that waste complies with the Paint Filter Test (EPA 9095) for No Free Liquids. The hazardous liquids are securely trapped within the superabsobent polymer matrix, preventing the release of harmful substances into the surrounding environment. This method simplifies the management of liquid waste, whether from spills or excess materials. Once treated, the waste can be safely transported and disposed of in a certified, engineered landfill.

Advantages of Our Products

- FAST-ACTING, less time spend.

- Eco-friendly & Non-biodegradable, non-toxic & harmless, safe for workers.

- Minimal waste volume expansion, volume increases less than 1%.

- No releasing liquid, locking liquid under pressure, stronger stability.

- Additional function like antibacterial and deodorizing can be added.

- Customized service available (for both products and packaging).

How to Use?

More Application Scenarios

Waste Landfills & Sludge Solidification

Dredging for Dredger

Environmental Remediation of Contaminated Sites

Operation Steps

Contact Us for Technical Advice

Fill out the form below to order samples, get more information or leave feedback.

Please let

us know if you have any questions, and our representative will reach out shortly.

About Us

Founded in 2009, SOCO Group has become one of the leading companies in the field of superabsorbent polymers(SAP), renowned for its exceptional professional manufacturing and comprehensive service capabilities. As an industrial brand under SOCO Group, Marco Sorb™ deeply cultivates SAP technology, and is willing to cooperate with friends from all walks of life to create a better future.

Leveraging R&D capabilties and manufacturing facilities, SOCO Group focuses on customer needs to provide high-quality, customized products and services. We not only specialize deeply in the SAP segment but also pioneer and lead the industry with our continuous innovation, development, service, and collaboration under the “SAP++”concept.

SOCO Group is committed to sustainable development practices. We provide proprietary SAP++ solutions for agriculture, industry, and other scenarios, dedicated to water conservation, water retention, water treatment, and efficient water resource utilization. By harnessing the power of technology, we drive social progress and environmental harmony, contributing our expertise and efforts to the sustainable management and utilization of global water resources.

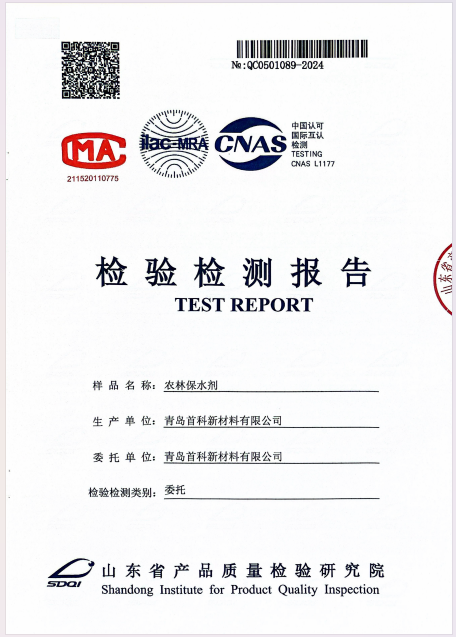

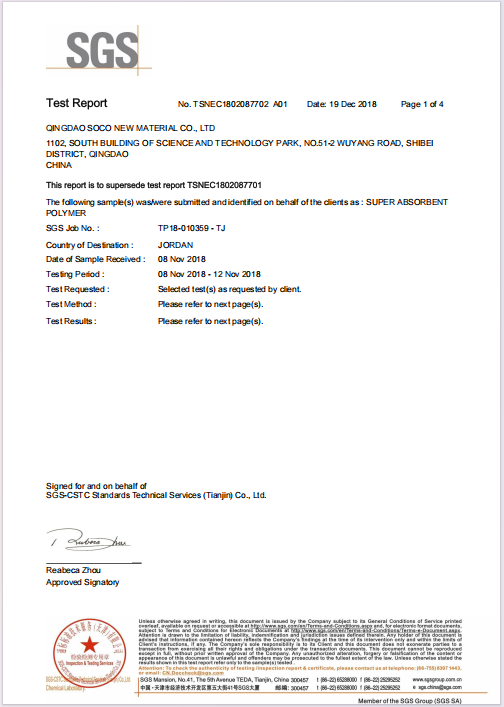

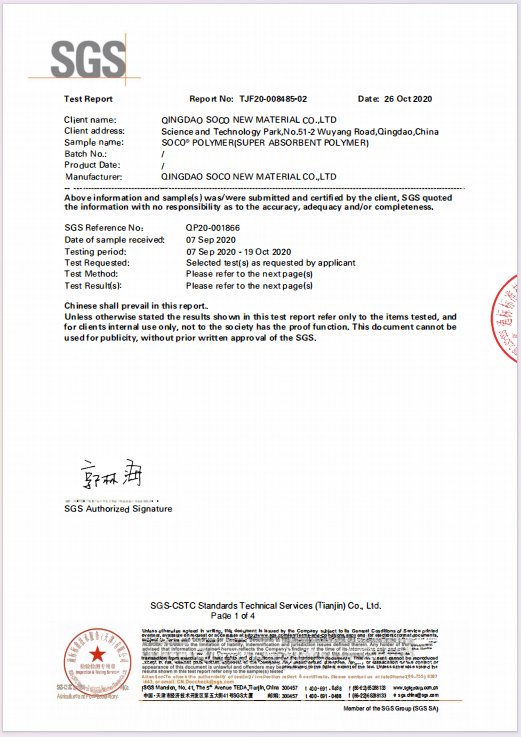

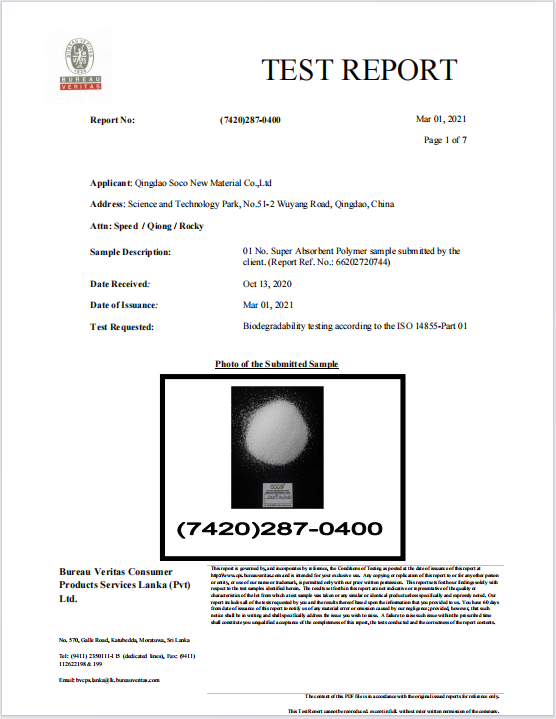

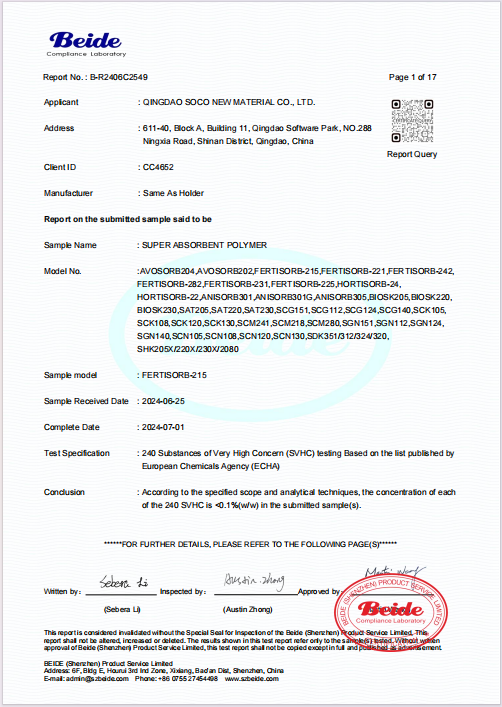

Comprehensive certifications and rigorous testing ensure that SOCO’s products cosistently meet the highest quality standards.

Certifications

Comprehensive certifications and rigorous testing ensure that SOCO’s products consistently meet the highest quality standards

FAQ

- 90% Less Material Needed: Only 0.5–1.5% SAP by weight vs. 10–25% cement or 100–200% sawdust.

- Instant Solidification: Works in 20–30 minutes (vs. days/weeks for cement).

- Zero Leachate Risk: Passes EPA 9095B Paint Filter Test—unlike sawdust.

- Cost Savings: Reduces disposal costs by 35–60% due to minimal volume expansion (<1%).

- Complies with EPA 40 CFR Part 503 (USA) and EU Directive 86/278/EEC.

- Non-Toxic & Heavy Metal-Free: Certified by SGS, RoHS for safe disposal.

- Leachate Prevention: Chemically locks liquids to avoid groundwater contamination.

- Full regional certification documents available upon request.

- Oil/Water Separation: Works on drilling muds, fracking fluids, oily scraps.

- Custom Blends: Adaptable for coal ash (2–5%) or toxic sludge (with antibacterial options).

- Global Proof: Used in 120+ countries for mining, dredging, spills.

- Faster ROI: Most clients recover investment within 1–3 projects.

- Cost Cuts: 60–80% material cost savings, 50–90% lower transport fees.

- Simple Equipment: Mix with excavators—no filters/kilns needed.

- Hidden Cost Eliminator: Avoids project delays, fines, and leachate treatment.